3D Printing Comes to Kitware

After evolving for several decades, 3D printing has finally reached the consumer market. Today, it is possible to access 3D printers with a wide variety of features and characteristics at prices ranging from $300 to $3,000.

Last month, our first two 3D printers arrived at Kitware. Since then, Kitwareans have been busy exploring the realm of possibilities involving the printers’ interplay with our open source platforms for visualization, image analysis, and computer vision.

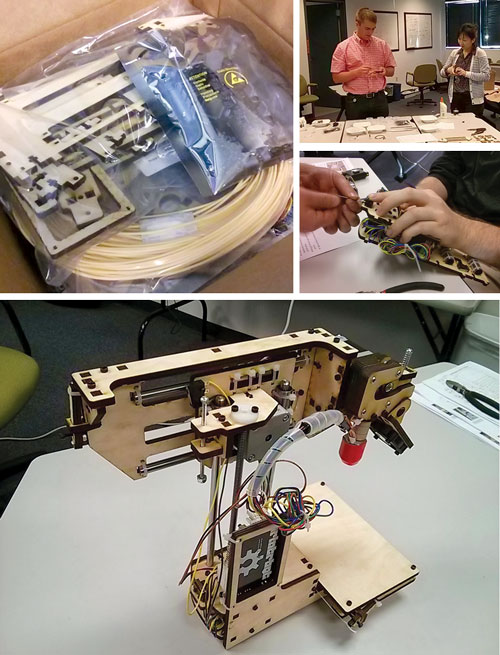

The Printrbot

The first printer to arrive was the humble Printrbot, a fully Open Source/Open Hardware printer. The Printrbot comes disassembled in a box. The structural parts are laser-cut wooden plates, which fit together with ingenious connections that give the printer a simultaneously retro and futuristic look.

Following its well-detailed instructions, it took us close to seven hours to assemble the Printrbot. The Printrbot can be run from Windows, Mac, or Linux machines by

using Repetier.

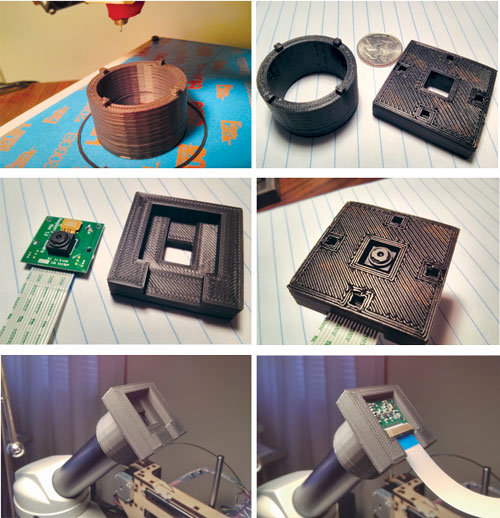

Using this printer, we created adapters to optical instruments. For example, we created an adapter to connect the Raspberry Pi Camera to a small low-cost microscope.

The model was created with OpenSCAD, processed with Slic3r to generate G-Code, and printed from Repetier.

This model is now available at http://www.thingiverse.com/thing:214466 and is distributed under a Creative Commons by Attribution 4.0 license.

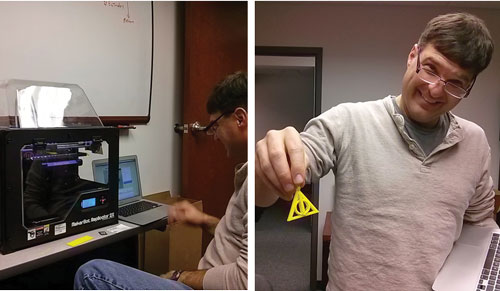

The Makerbot Replicator 2X

The second printer, the Makerbot Replicator 2X, arrived a week after the Printrbot. It required much less assembly. The Makerbot Replicator 2X is an experimental version of the Replicator model.

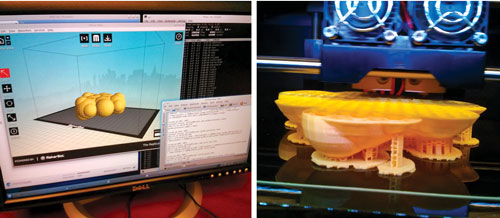

(top) Motorcycle model is from a fluid flow simulation that is commonly presented in ParaView. (bottom) Classic teapot model from Utah. More information can be found at http://en.wikipedia.org/wiki/Utah_teapot.

Model of a caffeine molecule. For more information, visit http://www.thingiverse.com/thing:14114.

One common method for printing models is to first generate an STL file. This is something we can do directly with VTK or ParaView. Once generated, the STL file is loaded into the Makerbot application. In the case of the Printrbot, the file is loaded into Repetier, which then uses Slic3r. From the STL model, a full sequence of movements is computed for the printer head extruders to draw the object layer by layer.

Depending on the geometry, some models may need to be printed with supports (see the motorcycle and the caffeine molecule pictures for examples). In certain cases, adding a supporting base, known as a raft, helps to keep the multiple parts of a model together as it is being printed.

Although 3D printing has now reached the consumer market, 3D printers are still more like “tools” than they are “appliances.” That is, there are many parameters that need to be taken into account and that may need to be adjusted to print different models. Examples include the temperature in the extruders, the type of plastic material (ABS/PLA), the temperature of the platform, and the thickness of the layers. For the Makers community, the printer’s flexibility is considered a nice feature, as it leaves those using the 3D printers with a fair amount of control.

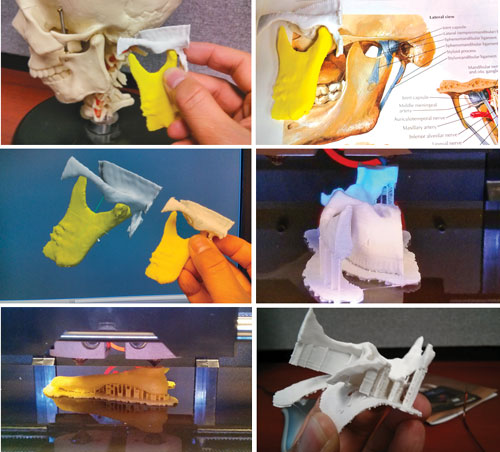

Using the Markerbot Replicator 2X and ABS plastic, we printed bone models that were originally segmented with Slic3r. The models were reoriented with Paraview before they were printed separately. The models correspond to sections of the Mandibular bone and the Temporal bone.

What is Next?

As we grow more familiar with the 3D printing process, we are starting to explore synergies with 3D medical imaging, especially with the segmentation of anatomical structures and with the crafting of devices that can be coupled with sensors and small computing platforms such as the Arduinos and the Raspberry Pis.

Luis Ibáñez is a Technical Leader at Kitware, Inc. He is one of the main developers of the Insight Toolkit (ITK). Luis is a strong supporter of Open Access publishing and the verification of reproducibility in scientific publications.